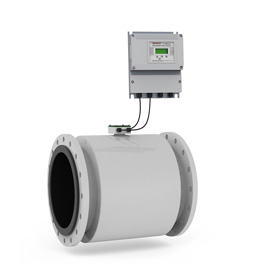

FTE series electromagnetic flowmeter is an instrument to measure the volume flow of conducting liquid according to Faraday's law of electromagnetic induction, which is a combination of hydrodynamics and electromagnetism.

Both in appearance and assembly, as well as in internal structure, this series of products have made new breakthroughs: angular appearance, rationalized structure with better magnetic field distribution.

At the same time also introduced the zinc spraying process, even in harsh environment, still can protect the electromagnetic flowmeter tube body surface, surface anticorrosion performance is superior.

■Applicable media: Acid, alkali, salt solution, water, sewage, corrosive liquid and mud, pulp, pulp and other conductive liquid, solid-liquid two phase.

■Type applications: fluid monitoring, refueling, filling, and high precision metering and measurement.

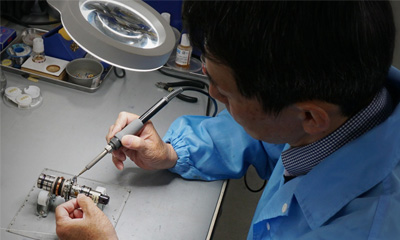

Faraday’s law of induction states that a metal rod moving in a magnetic field induces electrical voltage. This dynamo principle also governs the way electromagnetic flowmeters work.

As soon as the electrically charged particles of a fluid cross the artificial magnetic field generated by two field coils, an electric voltage is induced. This voltage, tapped by two measuring electrodes, is directly proportional to the velocity of flow and thus to the flow volume.

The magnetic field is generated by a pulsed direct current with alternating polarity. This ensures a stable zero point and makes the flow measurement insensitive to multiphase or inhomogeneous liquids, as well as low conductivity.

Electromagnetic flowmeters have been used throughout industries for more than 60 years. These meters are applicable for all conductive liquids, such as water, acids, alkalis, slurries and many others. Typical applications are monitoring of liquids, filling, dosing and precise measurement in custody transfer.

FTE-1600 Electromagnetic Flowmeter FAQ

Q: What is the FTE-1600 electromagnetic flowmeter used for?

A: The FTE-1600 electromagnetic flowmeter is designed to measure the flow rate of conductive liquids in various industries, including water and wastewater management, chemical, pharmaceutical, and food processing industries.